|

Introduction Hollow glass microspheres have multiple uses, but one of the most prominent is in the rubber industry to make products such as silicone rubber sealants. The major advantage that hollow glass microspheres provide is in terms of reduction in weight which allows for easy application for smooth transportation. PETRA MicroLite glass microsphere provides adequate insulation, durability, and stability which not only aid transportation but other applications as well. How is it used With Rubber? In terms of research, it is to be understood that the size of a particle, its capability with regard to bonding, and the load it has in determining strength, resistance, and rigidity in certain composites. Several researches also came to the conclusion that the properties in rubber were significantly enhanced when hollow glass microsphere was incorporated in them. Studies also suggest that when something has viscosity which is low melting in nature than that can be made by using hollow glass microspheres in polyester and epoxy resins. In another study, the behaviour of hollow glass microspheres was studied in terms of fracture and strength when incorporated in composites such as rubber. The hollow glass microspheres have more strength in comparison to the production of the composite independently. Further, when diverse composites were prepared from hollow glass microspheres, the observation was made that the durability of the material becomes higher when the hollow glass microsphere is high in density in the material during incorporation. In addition, the capacity for absorption of energy of the material increased to about 40% through the use hollow glass microsphere. One of the most important studies was with regard to the dielectric nature of the hollow glass microspheres which were filled with substituting composites and in this regard, it was noted that the consistency increased and losses reduced in terms of dielectric when hollow glass microspheres were added in increased quantity. Further in the context of fracture in terms of hollow glass microsphere, it is noted that the incorporation of the microspheres actually enhanced the flexural modulus and reduced the toughness and strength in terms of fracture. In terms of silicon rubbers, it is observed that the density and conductivity of these products increase with the addition of hollow glass microspheres. Silicone-induced rubbers are an essential product and the main composition of this product is made of SiOsi bonds. In place of rubber without silicone, silicone-induced rubber proves to have a high resistance to both increase and decrease in temperature, it is resistant to changes in weather, it has enhanced insulation in terms of electricity, and is also resistant to erosion along with the presence of physiological inertia. This sort of rubber is widely utilised in the aerospace industry, electrical products, biomedical industry, power plants, and other such industries. Hollow glass microspheres make for a very suitable filler that is non-metallic in nature. The distinct structure of the hollow glass microsphere allows it to light in terms of weight, have high strength, and provide insulation which allows for them to be used in foam, materials related to aerospace as well as buoyancy. The hollow microsphere is a very special material that is also inorganic in nature and has very diverse uses. The most distinct benefit of their hollow cavity is that it provides for increased isolation with regard to heat and has a very airy density. Thus, in terms of practical application in the rubber industry, one very important aspect is that of its incorporation in silicone rubber which encompasses as a filler not only intact spheres, but also fractured ones in separate ratios. The use in the rubber industry also suggests that even when the hollow glass microspheres are broken, it rather increased these properties which have been discussed above. PETRA MicroLite GM provides all these characteristics that can be useful in the rubber industry.

0 Comments

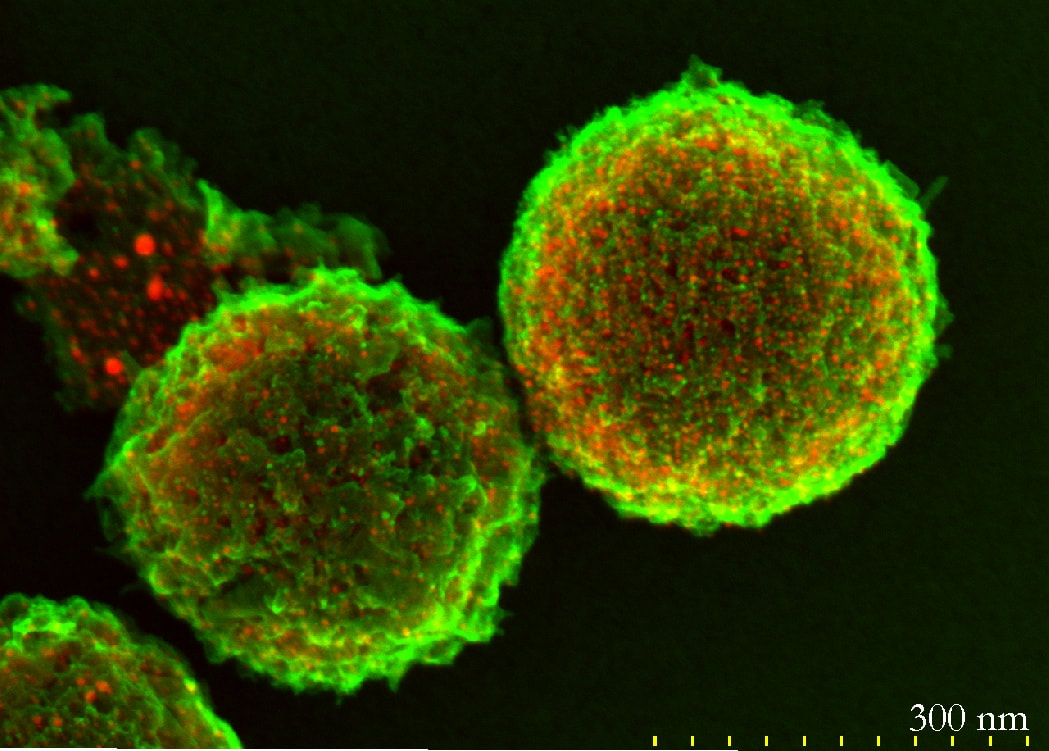

What are Glass Microspheres - Glass Microspheres are microscopic spheres of glass manufactured for extensive uses in research, medicine, consumer goods, and many other industries. They possess a high strength to density ratio which makes them very lightweight. They are made out of soda-lime borosilicate glass and can survive strong processing. How is Glass Microspheres Made - Microsphere are made from glass, ceramic, carbon, or plastic depending on their applications. Solid glass microsphere is manufactured by the direct burning of glass powders while hollow glass microspheres are produced by adding blowing agents to glass powder. The presence of additives makes them chemically inert and water-resistant. Physical Characteristics - They have a smooth and nonporous surface and spherical which gives them an edge over the irregular shaped additives. These engineered glass microspheres are eco-friendly and fire-resistant with high compressive strength. Uses of Glass Microsphere - Glass Microspheres find their uses in many applications like gas plasma displays, automotive mirrors, electronic displays, flip-chip technology, filters, microscopy, and electronic equipment. Hollow Glass Microsphere, also used in syntactic foams and particulate composites and reflective paints. Hollow Glass Microspheres- The reduction in the density of the thermally treated glass depicts that the particles are hollow. These hollow particles are majorly used as lightweight fillers. These are high-performance and cost-effective fillers and Hollow Glass Microspheres Manufacturers are committed to global services with more innovations pouring in. This glass type is amorphous and comes with high purity grades. Hollow Glass Microsphere, also called bubbles, micro-bubbles, or micro balloons and greatly improve the buoyancy of materials. The qualities of these hollow glass microspheres are-

Hollow Glass Spheres Drilling Fluids - Hollow glass hemispheres are inert materials and are used as density reducing agents. In the oil and gas industries, they are used for reducing the density of drilling fluids and cement blends. The most important physical properties of the microspheres for oil field applications are their low specific gravity and high collapse strength. Lesser product is required to achieve the drilling fluid target density which saves a lot of costs. The hollow glass hemispheres are potential elements for hydrogen storage due to the low density they possess. They are also non-toxic in nature and fire-safe which makes them non-explosive. The added advantages are that it results in zero environmental pollution and are mechanically strong and usable. A wide range of input is offered by hollow glass hemisphere manufacturers. These are small but growing elements in many industrial uses.

Cenosphere has high density of Silica & Alumina with different air and gases in it. Hollow Ceramic Microsphere is another name of Cenosphere. They are found naturally from the process of burning of coal-fired power plants, and has similar properties of manufactured Hollow-Sphered Products. They have hollow spherical structure which helps it to use in different industrial application with their superior properties like high thermal resistance, high strength, low bulk density and high workability. Manufacturing advantages of hollow ceramic microsphere is that it improves flowability and provides distribution of filler material. Because of its natural properties microsphere can be used in wet slurry or dry form. Hollow ceramic microsphere provides low surface area-to-volume ratio with easy application. It has great inert properties they are not much affected by water, alkalis, solvents or acids. They are 30% lighter than all resins and 70% lighter among other minerals that are currently used as fillers. Cenosphere - Manufacturing Aspects

The core reason of using cenospheres in concrete is its light weight from sand. Its Density is 0.7 which is very less as compared to the density of sand i.e 2.65 and water i.e 1.0 Workability Enhancer Particles of hollow ceramic microsphere(Fillit) are very minute due to which it behaves like a microscopic ball bearings in a concrete mix. Due to microscopic ball bearings effect, the workability increases. Bulk Filler Cenospheres are ideal to use in cement grout slurry because it has light colours and fine particles which helps in reducing the shrinkage. Uses of Cenosphere Uses of Cenospheres are explained below: Aerospace: In aerospace it is used in ceramic insulation, tortuous path matrix, propeller blades. Ceramics: In ceramics it is used in Tiles, firebricks, coatings, refractory, insulating materials, high temperature cement. Construction: In construction it is used in acoustic enhancement, acrylic, adhesives, coatings, backer board, wall panels, cements, cultured marble, epoxy, explosives, Exterior Insulation Finishing Systems(EIFS), fiberglass, laminates, light weight aggregate, synthetic wood, spackle, carpet backing, geothermal cements, concrete fiber board, joint compound, wood fillers. Coatings: In coatings it is used in highways, driveways, underground pipes etc. Automotive: In automotive it is used in soundproofing, under-coatings, brake pads, sealants, body fillers and putties etc. Oil Field: In oil field it is used in cementing, drilling muds(decreasing slurry density without increased water content). Plastic: In plastic it is used in Polyethylene, PVC, compounding film, urethane potting compounds etc. Benefits of Cenosphere

Cenosphere and microsphere has many industrial applications. The diverse products that we find in the market have these products as one of the many ingredients used. Most of the cosmetic products, paints, and grinding media have one or more of these items in them. As such there is a specific segment of buyers that are interested in these products. The ever increasing demand of these items has led to the growth of manufacturing companies that deal in microsphere and cenosphere.

Ceramic Microsphere Microspheres that are made out of natural and synthetic materials are available in different varieties. Ceramic microspheres are one such variety. It is used mainly for commercial purposes. They are used mainly for grinding media. Generally, microscopes vary in quality, size, distribution and even sphericity. They are semi – transparent in appearance and are quite unique in their appearance. What is Hollow Microsphere? Another popular variety of microsphere, hollow ones is used as additives. They help to lower the material’s density. They are used in spray drying technique as well as a solvent diffusion method. This type of microsphere is manufactured under extreme heat. Ceramic Hollow Beads Ceramic hollow beads are used mainly used in the paint industry. They improve the quality of the paint by improving the volume and density of the product. After application on the wall, the ceramic beads tend to shrink thereby creating a tightly packed film on the wall. What are Hollow Spheres? With a fraction of density compared to resins, hollow spheres have the capacity to displace heavy materials. They can add volume and reduce the density of a product. Moreover, compared to resins they are highly cost-effective. Hollow Bubbles Made out of aluminum and silica, hollow bubbles have lower density with higher strength. They are basically nano particles with a hard surface area. Their size varies between 10 to 300 microns. What is a Floating Fly Ash Balloon? Manufacturing floating fly ash balloon are found in areas where the floating ash is discharged. They account for 1% of the fly ash collected from thermal plants. In order to improve the quality of floating fly ash balloon, it is further cleaned through froth floatation and then dried before they are dispatched to the different industries. What is Hollow Balloon? Crafted out of aluminum and silica, hollow balloons have ceramic properties. Their size varies up to 500 microns and has the capacity to lower the density of materials due to the presence of pressurized gas inside the balls. Buy from Trusted Manufacturing Company No matter whichever variety of microspheres you are purchasing, always rely on certified manufacturing companies. You will find many companies dealing in cenosphere and microsphere, but, not all of them are up to the mark. When you check out the company, find out about the laboratory where these items are manufactured, the type of equipment used and whether skilled professionals are involved in the manufacturing of these items. A lot depends on the manufacturer and the manufacturing procedure followed. Petra Buildcare Products is a global manufacturing company based in Bhavnagar, Gujarat. With more than a decade of experience, we offer solutions based services to multiple companies across the globe. Our strict quality measures along with attention to detail have made us what we are. Since, 2003, we are exporting Cenosphere across countries like South East Asia, Europe, USA, UAE, Japan, Middle East and North African countries. We have state of the art infrastructure with in-house warehouse for storing the products. Our professionals are well versed and technically sound thereby making them experts in their concerned field.

Why Petra Buildcare Products? As a leading manufacturer of Cenosphere, we have constantly upgraded our knowledge and skills so as to offer the best possible service that is at par with international standards. For us client satisfaction is of utmost importance. Over the years, we have added many products in our cap. There are multiple reasons as to why you should hire us. In other words, our unique selling proposition can be shortlisted as below:

Cenosphere – what is it? A hollow microscopic ball is made using silica-aluminum and other ceramic elements of the minor variety. This element is derived from the inferno of coal related power plants. Since, the last 30 years, cenosphere is used for manufacturing diverse products. The size of cenosphere is relatively small ranging from 1 to 500 microns. These microscopic balls are quite strong and have a strength amounting to 3000+psi. Cenosphere Application These microscopic balls have use in many industries. They are used for manufacturing automotive components, bowling balls, surfboards, kayaks. Chemical Property of Cenosphere The chemical property of Cenosphere amounts to:

Microsphere what is it? Small, spherical particles, microspheres are manufactured from numerous synthetic and natural materials. Use of Microspheres Hollow microspheres are used to lower the density of a material they perform the role of additives. Ceramic microspheres are used as a grinding media. They are used in the cosmetic industry to reduce wrinkles and improve the quality of the skin. Micrometer range of Microsphere The micrometer range of microsphere varies from 1um to 100um. Buy Microspheres and Cenospheres from Trusted Manufacturer Both cenosphere and microsphere are valuable micro particles that have many applications in diverse industries. In order to buy these micro particles, make sure that you approach a trusted manufacture. If there is any inconsistency in the micro particles produced, it will fail to serve the purpose for which they are being used. Hence, keep in mind that you need to opt for a certified and authentic manufacturer who is in this business for several years. |

|